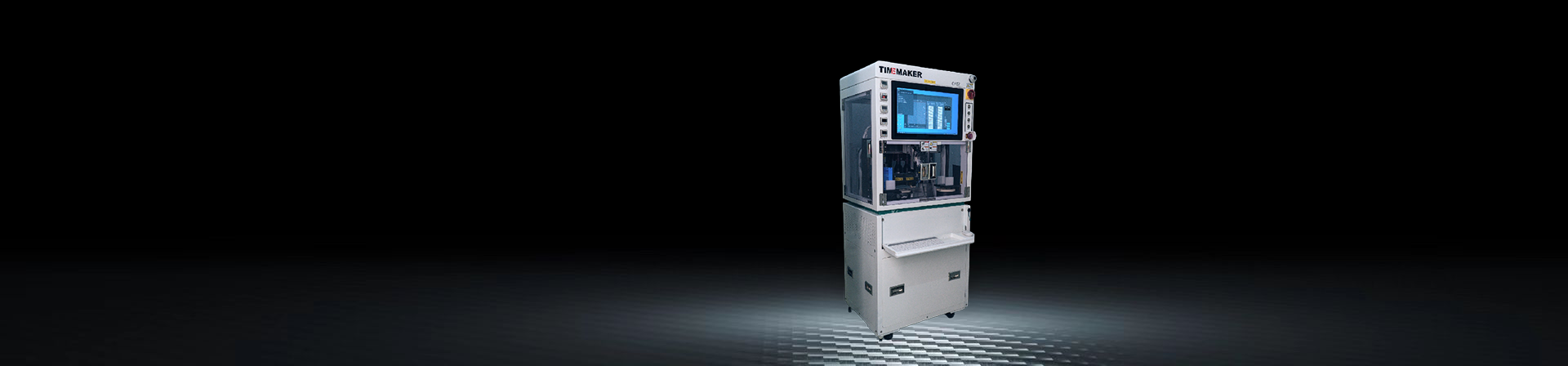

A high-precision wafer thickness tester specifically designed for magazine-fed operation, featuring automatic loading, visual positioning, thickness measurement, distance measurement, and automatic unloading. The machine also meets Class 100 cleanroom requirements.

● Non-contact, non-destructive optical film thickness measurement.

● Achieves high measurement repeatability using spectroscopic interferometry.

● Enables high-speed, real-time grinding inspection.

● Performs measurements through intermediate layers such as protective films and viewports.

● Supports long working distances and facilitates easy integration into production lines or equipment.

● Accommodates external signal triggering requirements for inline inspection.

● Utilizes proprietary analysis algorithms (patent obtained) optimized for film thickness measurement.

● Capable of automatic film thickness distribution mapping (optional feature).