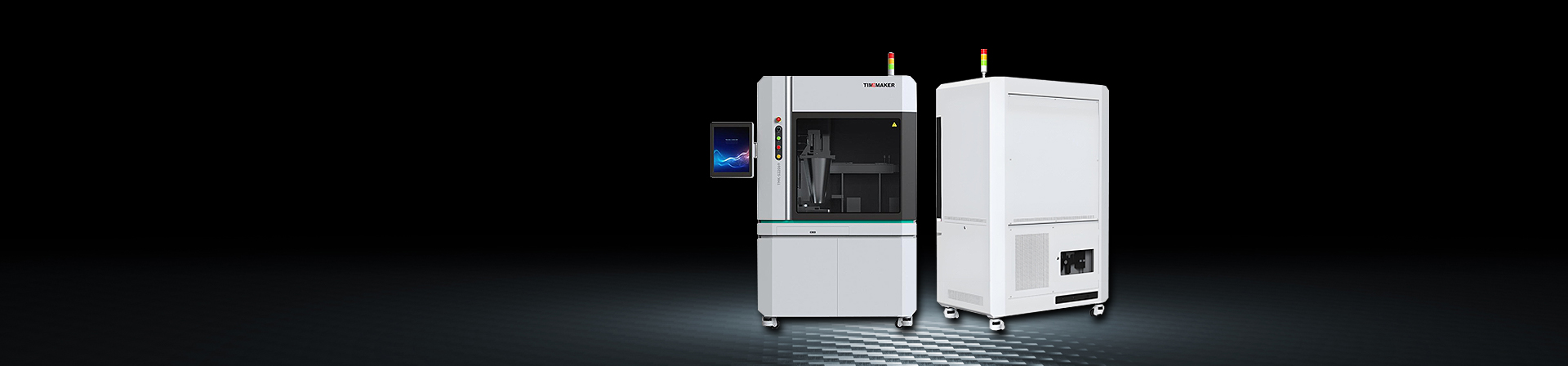

A high-precision mask alignment exposure system designed for cartridge-based feeding, featuring automatic loading, mask and wafer leveling, automatic front-back alignment, exposure, and automatic unloading. The system meets Class 100 cleanroom requirements. Applications include MEMS manufacturing, CMOS image sensors, memory devices, acoustic components, microfluidic chips, and compound semiconductors.

● Features an automatic parallel adjustment mechanism for high-precision setting of the proximity gap between the mask and wafer.

● Achieves high-precision alignment through proprietary high-speed image processing technology.

● Enables automatic dual-side alignment of wafer front and back surfaces using multiple vision systems (optional).

● Image processing technology enables pre-alignment for thin substrates, warped substrates, and fragile wafers like quartz (optional).

● A proprietary contact pressure precision control mechanism ensures high-precision proximity between the wafer and mask.

● Vacuum suction via a wafer-back manipulator achieves high-speed, high-precision, and stable automated handling.