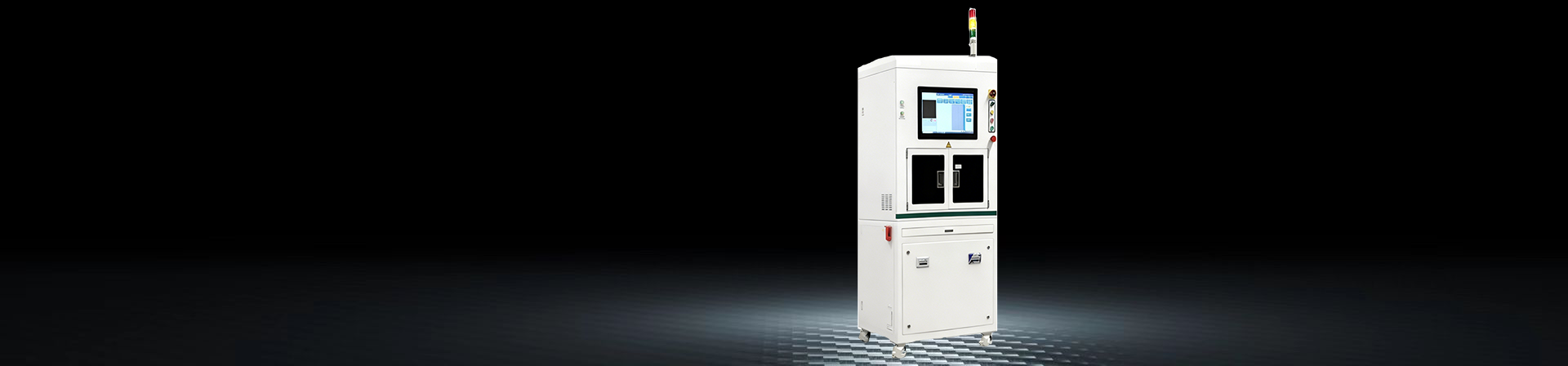

Specifically designed for precise edge chamfering of wafers made from materials such as quartz, silicon carbide, or sapphire. This process eliminates burrs and sharp edges generated during cutting, enhances wafer edge quality, and ensures yield and safety in subsequent chip manufacturing processes. Widely applied in semiconductor manufacturing, optical lens production, and medical device industries. Improves material edge quality and machining precision.

● Custom development available to meet client requirements.

● Chamfering precision up to 0.02mm.

● Custom-developed specialized sintered emery grinding heads.

● Fully automated production with automatic loading and unloading.